Energy conversion devices I

OER (oxygen evolution reaction) is a crucial process in energy conversion and storage, especially in water electrolysis Currently, precious metals and their oxide materials (IrO2, and RuO2), as state-of-the-art catalysts, are widely used in the OER process to reduce energy consumption and enhance energy conversion efficiency. However, these precious catalysts cannot satisfy large-scale production because of their scarcity, high cost, and poor durability. At present, the critical challenge is to explore alternative precious-metal-free catalysts for the promotion of the kinetically sluggish OER.

Energy conversion devices II

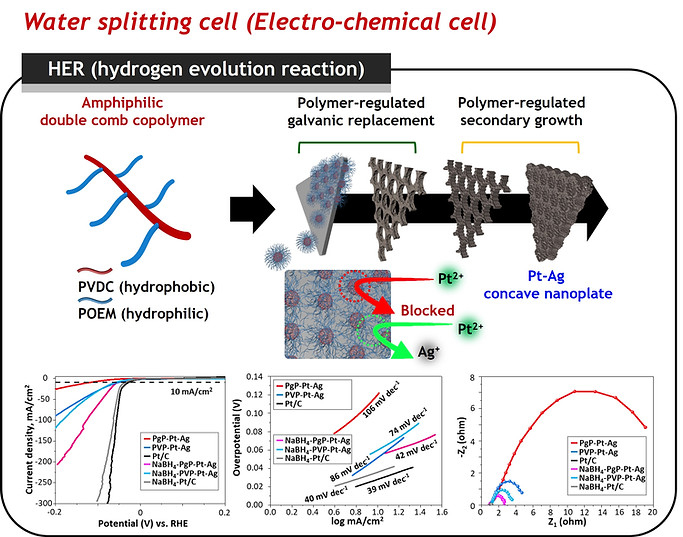

Electrocatalytic HER (hydrogen evolution reaction) in water splitting has been recently identified as an economical and sustainable method for H2 production. Platinum is the best known catalyst for HER and requires very small overpotentials even at high reaction rates in acidic solutions. However, the scarcity and high cost of Pt limits its widespread technological use. One critical requirement is the development of highly active, stable electrocatalysts composed of earth-abundant materials.

Energy conversion devices III

Among the various methods for producing hydrogen, water electrolysis techniques of water to obtain H2 and O2 have been widely studied. This process consists of two half-reactions: the hydrogen evolution reaction (HER) on one side and the oxygen evolution reaction (OER) on the other. Recent studies have developed catalysts for the two half reactions. However, the fabrication methods are rather complex, made in powder form, and are difficult to apply in actual commercialization. Meanwhile, the utilization of high performing and highly stable catalysts represented by noble metals such as iridium, ruthenium, and platinum entails high costs.

Energy conversion devices IV

Dye-sensitized solar cells (DSSC) are considered one of the most promising photovoltaic technology for powering electronic applications such as wireless sensors with indoor light. Their low cost and abundant materials, as well as their capability to be manufactured as thin and light-weight flexible solar modules highlight their potential for economic indoor photovoltaics. However, their fabrication methods must be scaled to industrial manufacturing with high photovoltaic efficiency and performance stability under typical indoor conditions.